SILICONEVALLEY CO., LTD

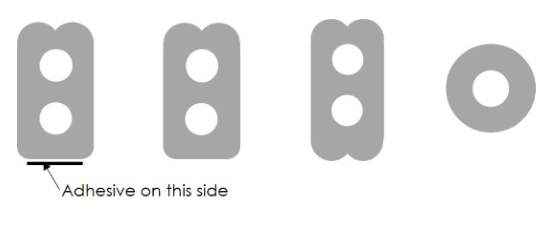

Silicone Rubber Gasket

Characteristics

Silicone rubber SGR-1355 is a material used for molded and extruded parts. The gaskets are used as an effective environmental sealing. The material is a platinum cured silicone and the rubber is All color Silicone rubber can easily stand heat, cold, moisture, UV, ozone and pressure over long times. Operating temperatures are between –55°C and +200°C.

Typical properties

| Item | Test Procedure | Unit | Post cured |

|---|---|---|---|

| Base material | - | - | Silicone |

| Density | ASTM D792 | g/㎤ | 1.4 |

| Hardness | ASTM D2240 | Shore A | 50 |

| Tensile strength | ASTM D412 | MPa | 4.9 |

| Elongation at break | ASTM D412 | % | 550 |

| Tear strength | ASTM D624 | N/㎜ | 13 |

| Compression set 22hr/180℃ | ASTM D395 | % | 60 |

| Flammability | UL94 | - | V0 |

RoHS information

SGR-1355 fulfils the requirements set by the EU Directive 2011/65/EU (RoHS).

Safety instructions

The SGR-1355 material is suitable for UL94, UL file number OCDT2-E514332. The silicone SGR-1355 is not dangerous to man or the environment. It is not classified according to Directive EG 1272/2008 (CLP) but a material safety data sheet can be sent on request.

Warrenty

The recommendations and data given are based on our experience to date, however, no liability can be assumed in connection with their usage and processing. Typical property data should not be used as a specification.