Silicone PAD for Hot Press

Product Properties

| Properties |

Unit |

HP0801 |

HP1001 |

HP1501/1502 |

HP2501/2502 |

| Thickness |

mm |

0.8 |

1.0 |

1.5 |

2.5 |

| Color |

- |

Red |

Red |

Red |

Red |

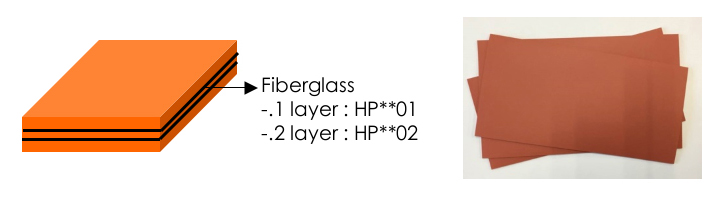

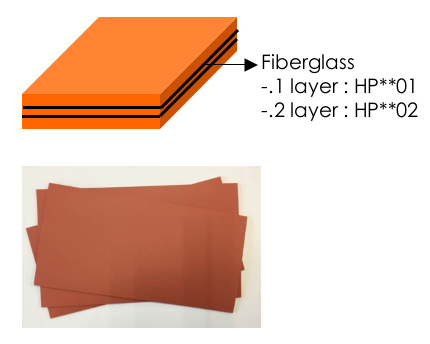

| Reinforcement |

- |

1 layer |

1 layer |

1&2 layer |

1&2 layer |

| Specific gravity |

- |

1.4 |

1.4 |

1.4 |

1.4 |

| Hardness |

Shore A |

80 |

80 |

80 |

80 |

| Elongation |

% |

< 10 |

< 10 |

< 10 |

< 10 |

| Temperature Range |

℃ |

-50 ~ 200 |

-50 ~ 200 |

-50 ~ 200 |

-50 ~ 200 |

| Tearing Strength |

Kgf/㎝ |

12.0 |

12.0 |

25 |

ASTM D624B |

| RoHS Compliant |

- |

Yes |

Yes |

Yes |

Yes |

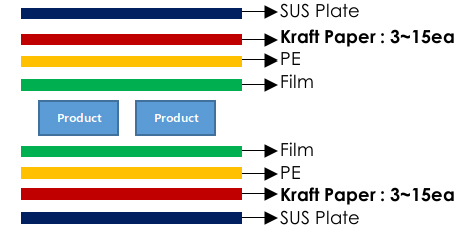

Application Method

Current Mfg. Condition :

- Manufacturing condition : 150’C/10hrs (150’C is hot plate temp.)

- Many FPCBs covered by kraft papers (>20papers/layer) pressured by hot plate during the mfg. process

- Kraft papers are disposed after 1 time usage

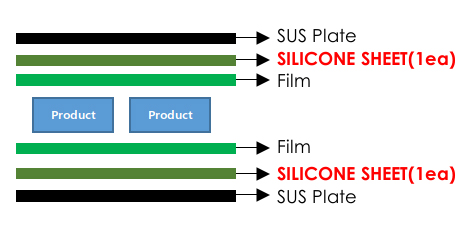

Expected benefits of using Silicone sheet

- Increase number of usage from 1 time (Kraft sheet) to >100times (Silicone sheet)

- Better heat resistance compared to that of Kraft paper

- Total cost benefits thanks to longer recyclable time up to 100times more than that of Kraft paper

Product Structure

siliconevalley@siliconevalley.co.kr