Thermally Conductive Encapsulant

Product Properties

| Uncured |

Unit |

STG-M608 |

STG-M250 |

STG-M300 |

| A |

B |

A |

B |

A |

B |

| color |

Visual |

White |

Darkgray |

White |

Darkgray |

White |

Darkgray |

| Viscosity(At 25℃) |

Cps |

3,200 |

3,200 |

10,000 |

10,000 |

80,000 |

80,000 |

| Mixed ratio |

wt% |

1 : 1 |

1 : 1 |

1 : 1 |

| Pot Life(at 25℃) |

Min. |

100 |

60 |

60 |

| Curing time(at 60℃) |

Min. |

60 |

30 |

30 |

| Cured |

Unit |

STG-M608 |

STG-M250 |

STG-M300 |

| Thermal conductivity |

W/mk |

0.7 |

2.5 |

3.0 |

| Appearance |

- |

Potting Gel |

| Hardness( Shore ) |

00 |

70±10 |

80±10 |

80±10 |

| Specific gravity |

g/㎤ |

1.7 |

3.0 |

3.0 |

| Volume resistivity |

Ω-㎝ |

1.0E+13 |

1.0E+12 |

1.0E+12 |

| Breakdown voltage |

KV/mm |

10 |

10 |

10 |

| Use Temperature |

℃ |

-50~200 |

| Flame rating |

UL94 |

V-0 |

Features( STG-M608 )

- Flame Resisting : UL94 V-0 recognized ( File No. : E306107 ) / UL746A ( HWI : 0 / HAI : 0 / CTI : 0 )

- Easy 1 : 1 mix ratio by weight.

- Excellent thermal conductivity.

- Potting of electronics parts requiring flammability and use under high Temperature

- Potting Gel for high voltage parts.

- To protect curing faulty, Do not contact phosphorus, sulfur, paraffin element, compound and BHT(Butylated Hydroxy Toluene) when curing silicone.

Packing Specification

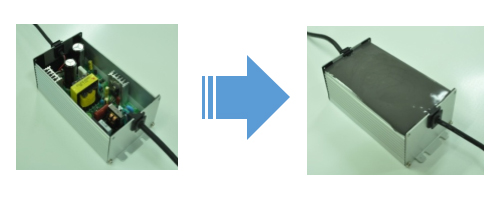

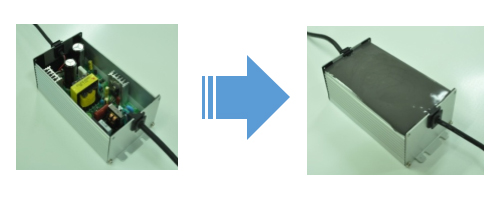

Applications

siliconevalley@siliconevalley.co.kr